Denflex Overdenture Attachment System

Each of the male and the female parts is made of metal, which has an excellent abrasion resistance with the special structure of the female part and can be used semi-permanently. It is an attachment with a new concept that enables the long life of the fixture even if the bone density is low or the length or diameter of the fixture is small as it does not transfer any excessive occlusal force to the fixture.

Free Angle Attachment Long Lifespan for Fixture Small Size No need for angled abutment Enhanced Durability Free Angle Attachment Long Lifespan for Fixture Small Size No need for angled abutment Enhanced Durability Free Angle Attachment Long Lifespan for Fixture Small Size No need for angled abutment Enhanced Durability

Problems of existing products

Due to the large volume, the attachment often protrudes from the buccolingual side of the denture, and due to limitations in the ability to buffer the force applied to the fixture, the lifespan is shortened in the case of implants with poor alveolar bone or small size where the fixture is placed. Since the structure that exerts the fastening force is made of polymer, its durability is limited, and frequent repairs are required. And when the installation angle between the installed fixtures is more than 20 off, a separate angled abutment is often needed. Additionally, if the bottom of the denture is not immediately corrected when the alveolar bone is absorbed over time, excessive shock is applied to the fixture, creating a structural vulnerability that shortens the lifespan of the fixture.

Advantages

Long Lifespan for Fixture

Although the alveolar bone resorption occurs over time and the denture is positioned below the original position, the structure in use can accommodate it inside the female part, so that the excessive occlusal force does not transfer to the fixture, thereby extending the life of the fixture.

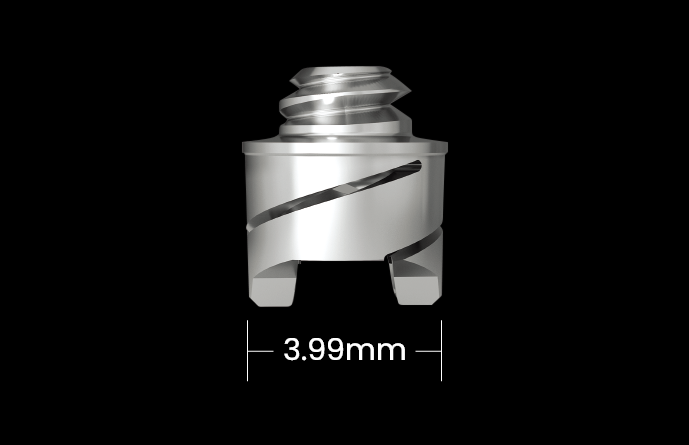

Small Size

The product does not protrude to the buccal aspect of the denture as it has a buffering function on the occlusal force and can be adjusted to the size as small as 3.7mm in diameter.

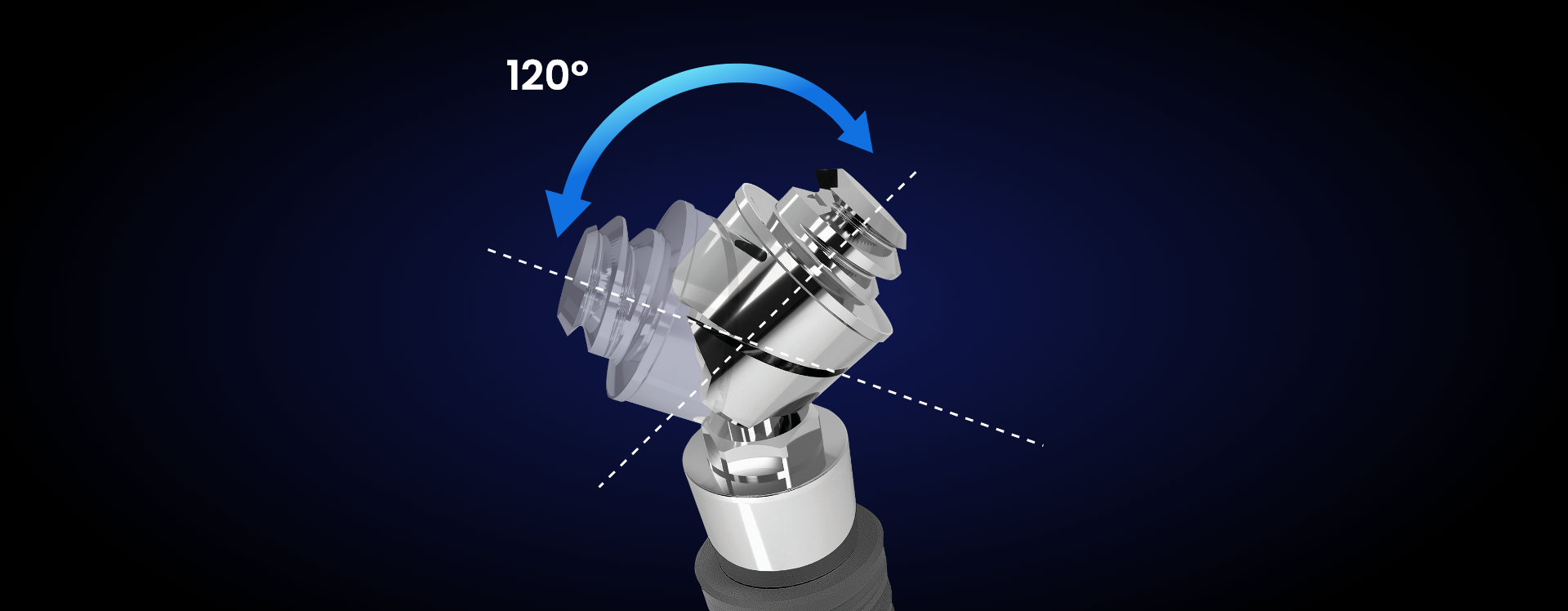

No Need for Angled Abutment

With the special structure of the Helical Attachment, the angle of placement between the fixtures can be accommodated by up to 35 degrees on one aspect and 70 degrees on both aspects.

Enhanced Durability

All components are made of metal to ensure an excellent ser vice life, and the special structure of the female part transfers minimal occlusal force to the fixture

A semi-permanent metallic material

Excellent shock buffer

FLOW DIAGRAM

How to install the female part (Attachment) in overdenture

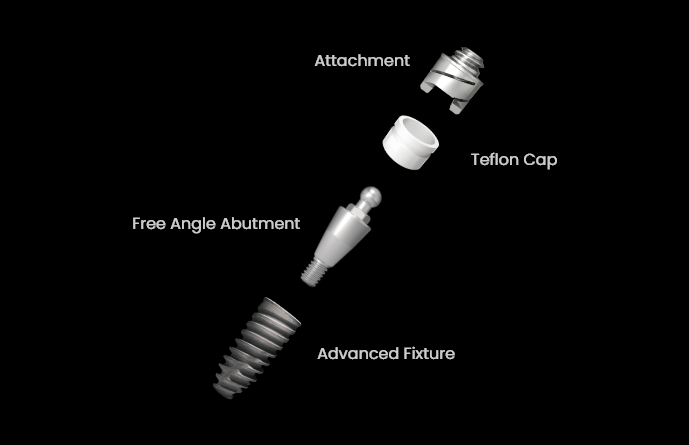

Attachment

Teflon Cap

Peek + Teflon Cap

* Supplied as a one part combined with Peek and Teflon Cap together.

Lab Analog

Free Angle Abutment

(Mini / Regular)

(Mini / Regular)

Advanced Fixture

1

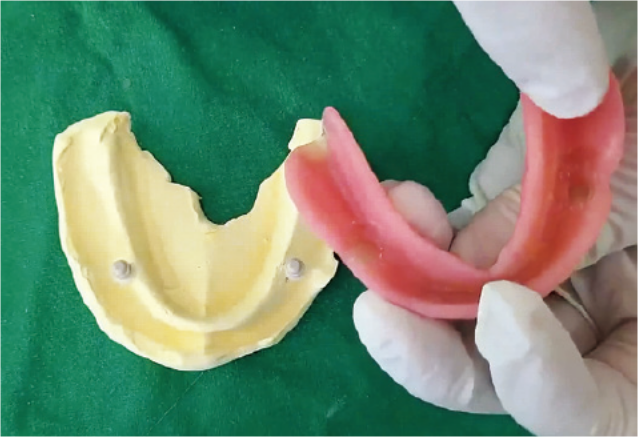

Make Overdenture using the Peek + Teflon Cap.

2

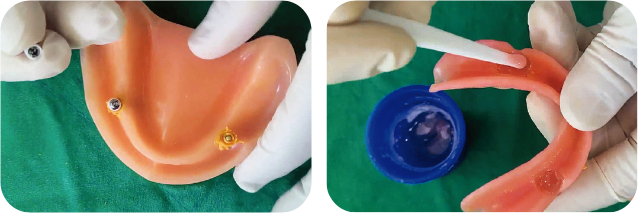

For the negative shape on the rubber, fill the rubber light body sufficiently and place Peek + Teflon Cap in parallel on ball abutment (male part).

3

Position Attachment + Teflon Cap (female part) on the negative shape and set it with resin.

SPECIFICATION

Product Information

Free Angle Abutment (Male Part)

| G/H (mm) | Mini | Regualr |

|---|---|---|

|

|

|

| 1 | DFFAA-M-D2GH1-OS | DFFAA-R-D2GH1-OS |

| 2 | DFFAA-M-D2GH2-OS | DFFAA-R-D2GH2-OS |

| 3 | DFFAA-M-D2GH3-OS | DFFAA-R-D2GH3-OS |

| 4 | DFFAA-M-D2GH4-OS | DFFAA-R-D2GH4-OS |

| 5 | DFFAA-M-D2GH5-OS | DFFAA-R-D2GH5-OS |

Free Angle Attachment (Female Part)

| Diameter | Length | Code No. |

|---|---|---|

| Ø 3.99 | 4.65 | DFFAA-O-D399-cc |

Teflon Cap

| Diameter | Length | Code No. | Remark |

|---|---|---|---|

| Ø 4.84 | 3.00 | DFFAA-T-D484-bb | for Attachment |

| Ø 5.30 | 2.10 | DFFAA-T-D530-aa | for Peek |

Peek

| Diameter | Length | Code No. |

|---|---|---|

| Ø 5.20 | 4.75 | DFFAA-P-D520-aa |

Lab Analog

| Diameter | Length | Code No. |

|---|---|---|

| Ø 4.0 | 6 | DFFAA-L-D4L6H-aa |

Torque Wrench

| Torque Scale | Code No. |

|---|---|

| 20-50Ncm | DFCTW-W-N5012-RH |

Driver

| Type | Length | Code No. | Remark |

|---|---|---|---|

| 1.2 Hex | 17 | DFFAA-D-H1217-OS | Removal Driver |

| 2.6 Hex | 18 | DFFAA-D-H2618-OS | Ball Driver |